Laser Photonics Rev: Non-inv Eng Enables Pol-pure Perov Micro No Ext Cav

source:Semiconductor Nanomaterials

keywords:

Time:2025-09-17

Source: Semiconductor Nanomaterials 8th Sep 2025

01 Overview of the Entire Text

Dynamic modulation of microcavity lasers is crucial for achieving stable single-mode operation with high monochromaticity, compact size, and directional emission. However, as the cavity size increases, the emergence of high-order transverse modes hinders efforts to expand the cavity size while maintaining stable single-mode operation. To date, no suitable physical mechanism has been found to achieve single-mode lasing independent of cavity size. Here, a breakthrough non-invasive technique for in-situ engineering of natural nanogrooves in large (20×20 μm) perovskite microplates (MPs) was developed through dynamically controlled vapor phase epitaxy. This technique enables unprecedentedly precise mode control to achieve optimal single-mode laser performance. Crucially, these well-defined grooves can alter the laser resonant modes within the microcavity, enabling a transition from whispering gallery modes (WGMs) to Fabry-Perot (F-P) modes. The optical anisotropy induced by the engineered groove structure also enables polarized laser emission with high polarization degree (close to 0.65). Additionally, numerical simulations elucidate the origin of cavity-free, high-quality (≈2660) and single-mode F-P laser behavior under large-scale conditions, which is attributed to the coupling of multiple cleaved cavities induced by the cracked groove structure in the perovskite MPs morphology. This study pioneers a mode-selective modulation approach for scalable polarization engineering of large-area single-mode micro-lasers, fundamentally advancing multifunctional integration in photonics and high-density optoelectronic systems.

02 Research Background

The development of microcavity lasers with compact size, high efficiency, high side-mode suppression ratio (SMSR), and directional emission is highly desirable for integrated photonic devices and optical communications. Currently, most semiconductor micro-lasers typically exhibit multi-mode operation due to the lack of mode selection mechanisms in their intrinsic cavities. To accelerate the practical application of micro-lasers, parameter control and optimization are crucial, such as achieving single-mode operation and polarization control. To achieve single-mode laser output, extensive mode selection work has been carried out within microcavities, including reducing cavity size, constructing various coupled cavities, utilizing the Vernier effect, implementing PT-symmetric structures, and other schemes. Despite these achievements, these methods inevitably lead to reduced resonator gain and microcavity quality due to the reduction in cavity size, the manufacturing complexity of constructing coupled cavities, the introduction of external cavities, and changes in excitation conditions, ultimately resulting in increased laser thresholds and unstable output characteristics. Additionally, although polarization laser emission can be achieved by incorporating polarization selection elements in the resonator, these techniques are often incompatible with micro-lasers.

Low-dimensional inorganic perovskite single crystals have emerged as promising candidates for constructing on-chip integrable high-quality polarization single-mode laser sources due to their excellent optical gain properties and microfabrication feasibility. Currently, the pursuit of single-mode lasing in perovskite micro/nanocrystals is a key and challenging aspect for next-generation optoelectronic applications. Over the years, groove engineering in perovskite single crystals has become a major approach for precise manipulation of microcavity modes. By designing the size and position of these grooves, the formation of higher-order modes can be effectively suppressed while guiding the light field along a specific propagation direction, thereby promoting single-mode laser output. Advanced manufacturing techniques such as nanoimprint lithography, etching, focused ion beam (FIB) milling, and laser ablation have enabled the precise engineering of perovskite micro/nanostructures with groove features, achieving precise control over light confinement and mode selection. Unfortunately, these operations are challenging and costly, often introducing defects or contamination during the manufacturing process, all of which can reduce the intrinsic quality of the crystal and compromise the laser performance of perovskite single crystals. More importantly, these existing mode selection methods mainly regulate the number of laser modes but fail to control the polarization state of the laser emission. Therefore, developing a simple, controllable, and non-destructive strategy to simultaneously achieve single-mode operation and polarization emission in perovskite micro-lasers is a promising but challenging frontier area.

03 Research Approach

single-mode laser systems and advanced photonic devices.

04 Research Contents

CsPbBr3 (CPB) microplates were fabricated on ultrathin mica substrates by a simple vapor phase epitaxy method in a two-zone tube furnace. Notably, the formation of groove structures within the CPB microplates was achieved by artificially controlling the cooling rate during the vapor phase epitaxy growth process. The detailed synthesis protocol is provided in the experimental section. Initially, the formation mechanism of these grooves within the microplates was systematically investigated, as shown in the figure. As previous studies have indicated, morphological defects (e.g., growth-induced

mismatch between the perovskite microplates and the mica substrate, inducing planar tensile strain in the CPB lattice to promote alignment with the mica lattice.

microplates of similar size and with the same number of grooves, the groove width increases with temperature. This thermal expansion difference intensifies the thermal stress concentration, causing the groove cracking on the microplates to exhibit a similar widening trend. This observation is directly related to the previous discussion, where the amplitude of thermal stress fluctuations was proven to be the key factor determining the final groove morphology in the perovskite microstructure.

The influence of different numbers of well-defined grooves on the lasing characteristics of perovskite microdisks was systematically

Surprisingly, the strategically embedded groove structures in perovskite microplates can fundamentally manipulate their associated laser characteristics. As shown in the figure, with the increase in the number of grooves, the emission spectrum evolves

Previous reports have indicated that morphological defects in materials can affect the laser characteristics of microcavities. The Q

fabricating perovskite micro-lasers with surface defect structures, the number of grooves must be carefully considered to ensure optimal laser performance. Furthermore, the influence of groove position distribution and width on the laser performance of perovskite microchips was systematically investigated. The study demonstrated that achieving high-performance single-mode laser output through coupled cavities also requires an appropriate cavity length ratio and a sufficiently narrow air gap to enhance the coupling efficiency between cavities and achieve resonance enhancement for single-mode output.

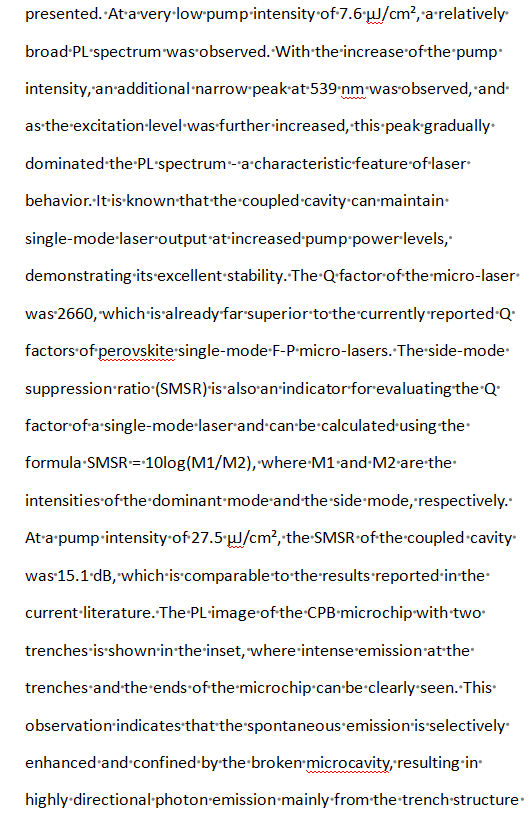

The laser characteristics of the CPB microchip with two embedded trenches that exhibited the best performance were analyzed in detail. First, the pump intensity-dependent PL spectra were

and the cavity edges.

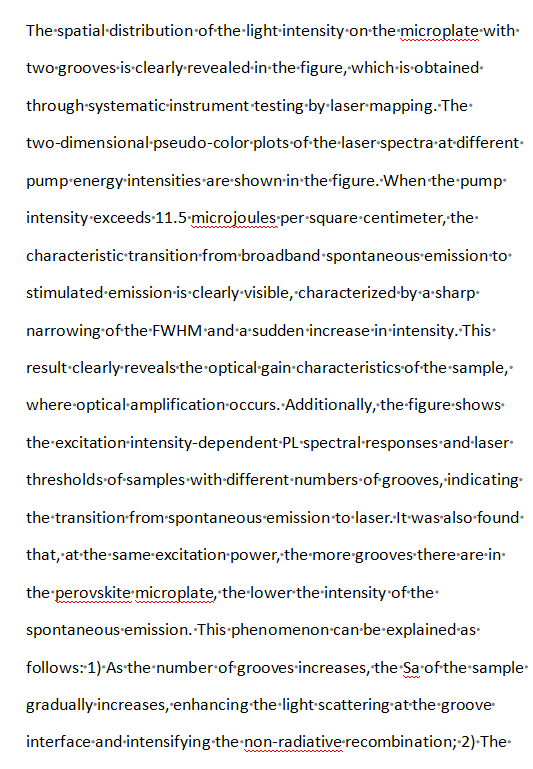

Further research was conducted on the influence of groove structures on the performance of CPB microchip lasers. As shown in the figure, the two-groove microchip exhibits nearly symmetrical groove positions and a uniform width distribution. The groove depth and microchip thickness were determined using atomic force microscopy (AFM) characterization. These cracked microcavities may affect the formation and selection of laser modes. The figure reveals significant electric field changes at the groove positions of the microchip due to the interaction of coupled cavities. Notably,

the coupled cavities are highly sensitive to the gap between the two cavities, where the scattering and diffraction effects influenced by the gap spacing play a crucial role in determining the coupling strength. It was found that grooves with widths approximately between 80 and 90 nanometers could achieve effective inter-cavity coupling. Therefore, the observed single-mode laser is attributed to the coupling effect produced by multiple cleaved cavities. FDTD simulation results indicate that the microcavities in the groove regions exhibit a relatively large free spectral range (FSR). Due to this characteristic, single-mode laser emission was observed in these microchips with engineered groove defects. The amplified electric field distributions at the microchip end faces and grooves are shown in the figure. Additionally, compared to the intact structure, the number of laser modes in the grooved microchip was significantly reduced, although single-mode operation was not achieved. This is because the width of the air gap in the coupled cavities plays a key role in determining the laser behavior. The electric field distribution of a perovskite microchip with an embedded groove (width approximately 165 nanometers) is shown in the figure. This larger air gap enhances the outward light scattering while reducing the optical transmission between the terminal microcavities, ultimately lowering their coupling efficiency. based on the above discussion, three fundamental conditions are required to achieve high-performance single-mode lasers in perovskite microchips: i) an optimal number of grooves; ii) a sufficiently narrow air gap to ensure coupling efficiency; iii) an appropriate distribution of groove positions.

The study of optical anisotropy in perovskite micro/nanostructures is crucial for the development of polarization-engineered photonic devices. The orthorhombic phase CPB microplates prepared, combined with their cracked morphology, can induce polarization-dependent optical properties. The optical anisotropy of the CPB microplates embedded in the grooves was confirmed by polarization-dependent Raman spectroscopy. A distinct Raman scattering peak was observed at 72 cm-1, corresponding to the Br-Pb-Br bending mode. The significant anisotropy and periodicity of the Br-Pb-Br bending mode near 72 cm-1 were revealed by the contour plot shown. The Raman scattering intensity was extracted and the related polar plot is shown in Figure S22, demonstrating a highly symmetric polarization dependence.

To study the emission anisotropy in the cavity-free microplates, 355-nm femtosecond laser was used to excite the samples. The laser spectra recorded at different polarization angles (θ) are shown in the figure, where the excitation intensity at θ = 0° is approximately five times that at θ = 90°. This obvious angle dependence clearly confirms the strong emission anisotropy in the CPB microplates embedded in the grooves. In the PL images, brighter luminescence was observed at θ = 0° compared to θ = 90°. The figure shows the detailed polarization dependence of the laser intensity as a function of the polarization angle, intuitively demonstrating that the maximum laser intensity is reached at 0° and 180°. The degree of polarization is defined as DOP = (Imax - Imin) / (Imax + Imin), and the calculated result is 0.65, indicating highly polarized laser emission. The figure reveals the modulation of the laser intensity under different polarization excitations, and the laser intensity modulation near 540 nm was detected. Clearly, by changing the polarization, repeatable laser emissions with periodic intensity modulation were observed, which indicates the stability potential of the CPB microplate microlasers. The results show that in these naturally embedded groove CPB microplates, laser intensity modulation and polarization control can be achieved, which is helpful for exploring and applying perovskite microstructures for new optical functions.

To demonstrate their potential for integration with photonic chips, the CPB microchip lasers embedded in trenches were successfully

neglected. These perovskite microchips with well-defined trenches exhibit stable and controllable lasing behavior on different substrates, suggesting their considerable potential for related chip integration.

Single-mode lasers that can operate continuously at high temperatures are highly attractive in both laser physics and practical applications. To evaluate the thermal stability of single-mode lasing in CPB micro-lasers with trench engineering, temperature-dependent measurements were conducted using a 355-nanometer femtosecond laser (35 microjoules per square centimeter) in the range of 295 to 395 Kelvin. As the temperature increased, a gradual decrease in laser intensity was observed, which was attributed to thermally enhanced non-radiative recombination. Notably, the laser mode position remained almost unchanged at different temperatures, indicating that the energy bandgap is insensitive to temperature within the measured range. The temperature-dependent variations in emission intensity and FWHM are shown in the figure. The FWHM of the CPB micro-laser monotonically broadened with temperature, reaching 1.14 nanometers at 395 Kelvin. More excitingly, these CPB micro-chips embedded in trenches exhibited excellent thermal stability, with only a 4.0% decrease in laser intensity after being exposed at 350 Kelvin for one hour. To further verify the stability of the micro-laser devices, a rigorous thermal cycling test was performed on the samples, and the integrated laser output intensity was monitored during two consecutive heating and cooling cycles. Figure 6g shows that during the cooling process of cycle (I), the laser intensity steadily increased and ultimately reached its maximum at 295 Kelvin, which was due to the enhanced radiative recombination rate and reduced Auger recombination loss. Notably, the laser intensity obtained during the cooling process was almost the same as that during the heating process, indicating that the sample is a robust gain medium with good thermal tolerance. Interestingly, the laser intensity evolution maintained a consistent trend in consecutive thermal cycles, demonstrating the stability and reproducibility of the CPB micro-laser. The above observations clearly indicate that the fabricated CPB micro-chips with natural trenches can serve as high-temperature laser materials, which expands existing applications and unlocks new potential.

4th Collaboration! What Brought the Global Laser Academic Guru to Chinese Univs & Leading Firms?

4th Collaboration! What Brought the Global Laser Academic Guru to Chinese Univs & Leading Firms? DNE Laser Foshan Smart Manufacturing Base Grand Opening: New Brand Image Starts New Journey

DNE Laser Foshan Smart Manufacturing Base Grand Opening: New Brand Image Starts New Journey Live: DMP GBA Expo – Laser Hard Tech Leads Industrial Smart Manufacturing New Wave

Live: DMP GBA Expo – Laser Hard Tech Leads Industrial Smart Manufacturing New Wave Scientists Develop Palm-sized Short-pulse Laser System: Efficiency Increased to 80%

Scientists Develop Palm-sized Short-pulse Laser System: Efficiency Increased to 80% Global LiDAR Giants Engage in Escalating Patent Wars

Global LiDAR Giants Engage in Escalating Patent Wars

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining Optizone Technology: 17 Years Devoted to Optics – High-Power Optics Mass-Production Pioneer

Optizone Technology: 17 Years Devoted to Optics – High-Power Optics Mass-Production Pioneer Zhuojie Laser: Breaking barriers via tech breakthroughs, aiming to lead high-end light sources

Zhuojie Laser: Breaking barriers via tech breakthroughs, aiming to lead high-end light sources Dr. Sun Linchao: Pioneer and Leader in China's Field of Medical Aesthetic Laser Therapy

Dr. Sun Linchao: Pioneer and Leader in China's Field of Medical Aesthetic Laser Therapy Guo Guangcan, CAS Academician & USTC Professor: Four Decades Chasing Quantum "Light"

more>>

Guo Guangcan, CAS Academician & USTC Professor: Four Decades Chasing Quantum "Light"

more>>